MUSKITA’s anodized finishes are timeless.

We have been anodizing aluminium since 1965. Anodized products produced over half a century ago can still be found today maintaining their original finish virtually untouched by time - a testament to the quality, experience and expertise of MUSKITA’s anodization process.

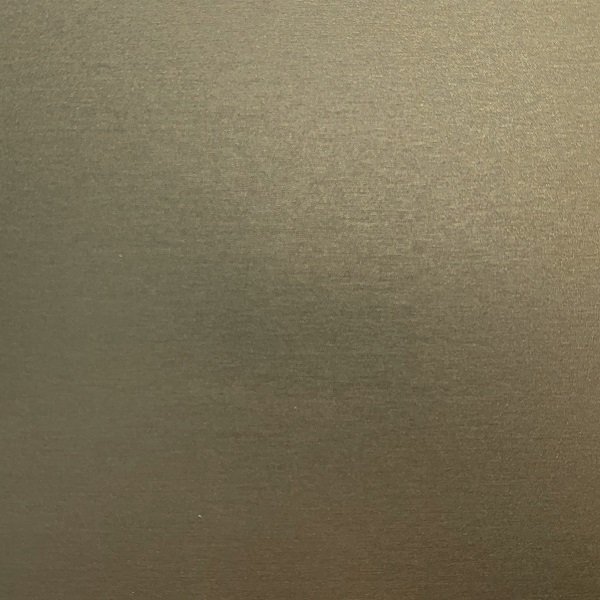

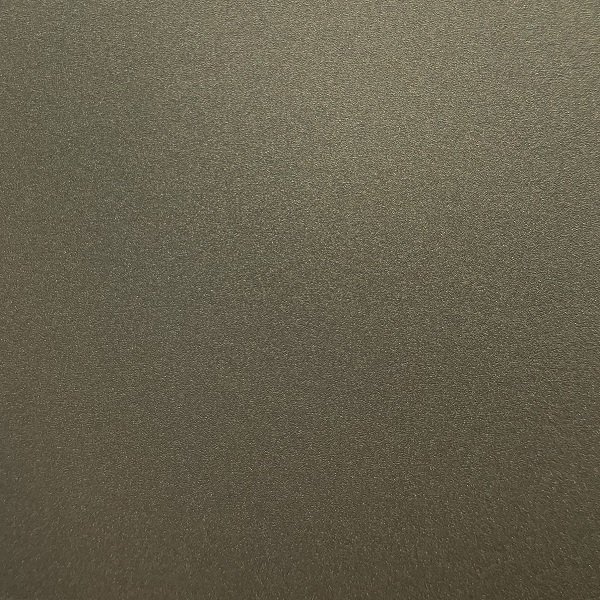

Available in a wide variety of refined metallic tones and luxurious tinted shades, MUSKITA's exclusive anodized finishes reveal the elegance and natural beauty of aluminium.

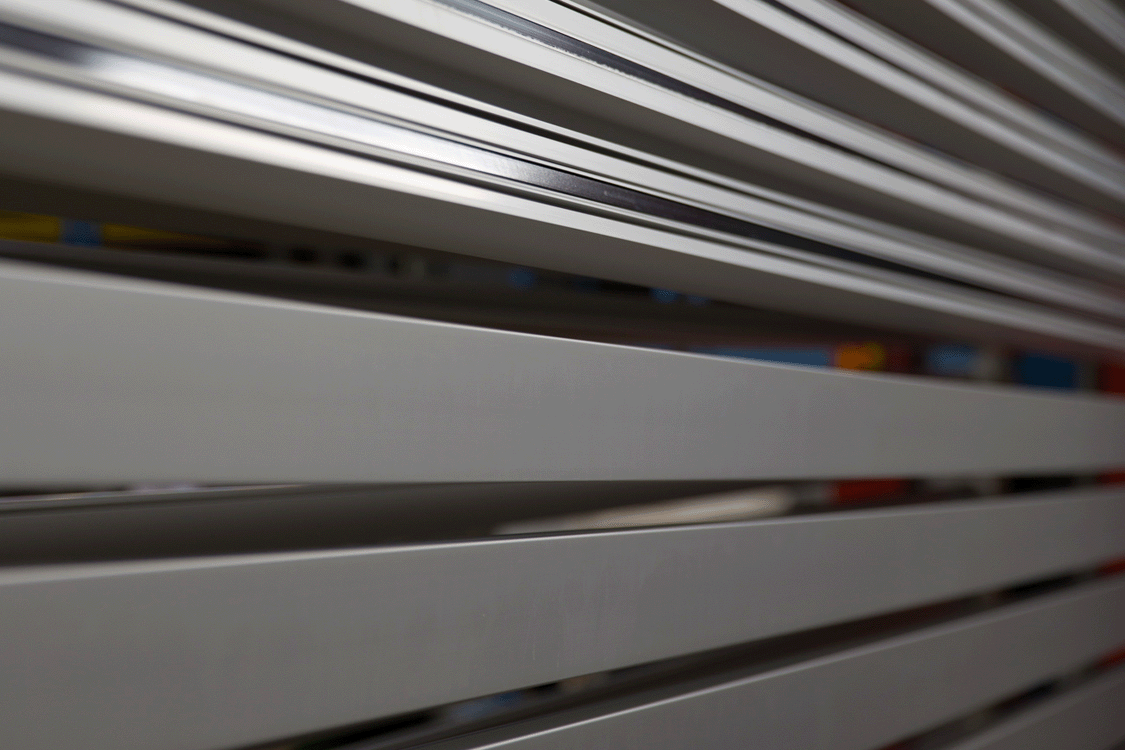

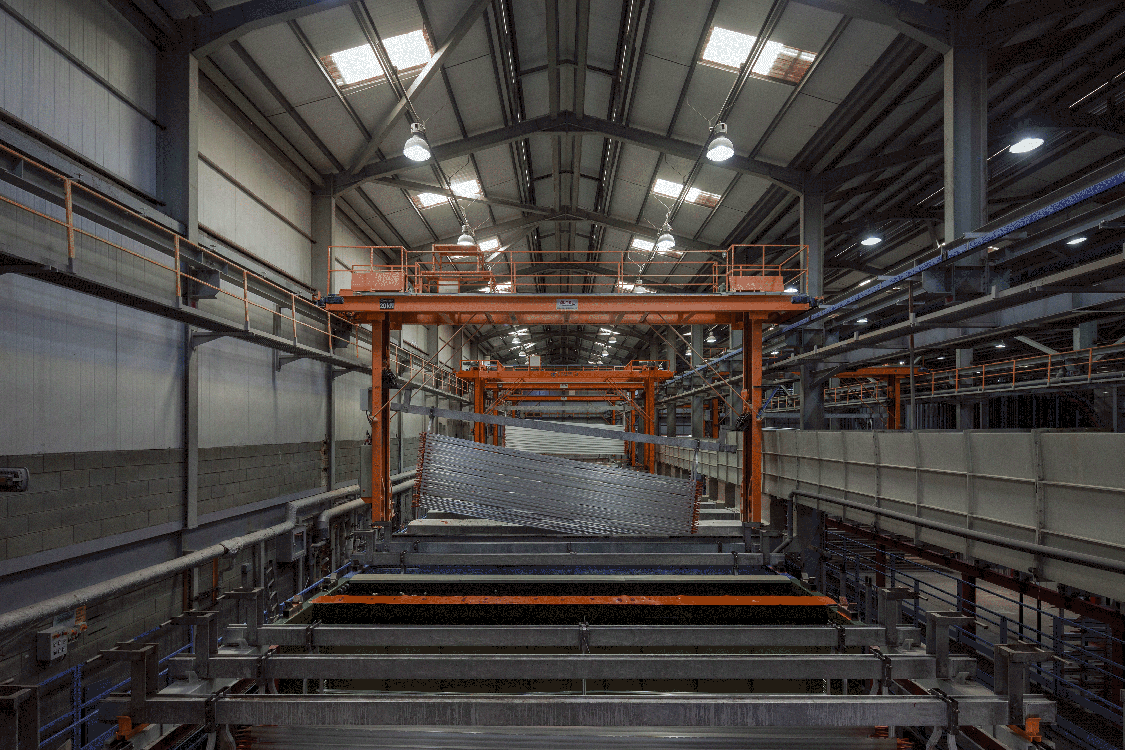

MUSKITA maintains and operates one of the most advanced anodizing plants worldwide utilizing state of the art robotic technology. Our vertically integrated production facilities combined with our in-house anodization process give us complete control over products quality, from raw materials to finished products, for outstanding results.

Our products are certified by the quality certification QUALANOD since 1996.

Anodizing is an electrochemical process where the aluminium is covered by a uniform layer of aluminium oxide via electrolysis. The metal is properly brushed, polished or blasted depending on the desired finish and goes through a series of cleaning chemicals. A solution of sulfuric acid acts as the electrolyte. A very high-power low-voltage direct current, uniformly oxidizes the work surface from the cathode (-) to the anode (+) thus the term “anodizing”. The process is completed by sealing the metal pores to maintain the highest resistant coating offered on aluminium.

Please note the colours & finishes shown here vary from the final product. For an accurate representation, visit our showrooms to see them in person.

Although anodizing has the highest weather resistance and needs minimum maintenance, it is recommended that the material be periodically cleaned. Recommended cleaning includes rinsing with water followed by a soft sponge with water and soap (such as dishwashing liquid), then rinsing with water and drying with a soft cloth. It is recommended that cleansing products have a pH between 5.5 – 8 (should neither be acidic or alkaline). Cleansing products which include chlorine or soda must be avoided. Construction materials such as cement, lime, plaster or adhesive tape must be removed immediately after installation. Moreover, silicone residue should be removed with cotton wool and blue spirit. It should be noted that in industrial and coastal areas cleaning of should be more frequent.