Changing environmental conditions and the high energy costs of cooling and heating buildings, necessitate the use of technologically advanced energy efficient aluminum systems.

For an apartment of 100 m², replacing 6 old frames with new thermal aluminum systems with a Uw = 2 [W/(m²K)], you can achieve up to €1000 per year in cost savings from heating and cooling.

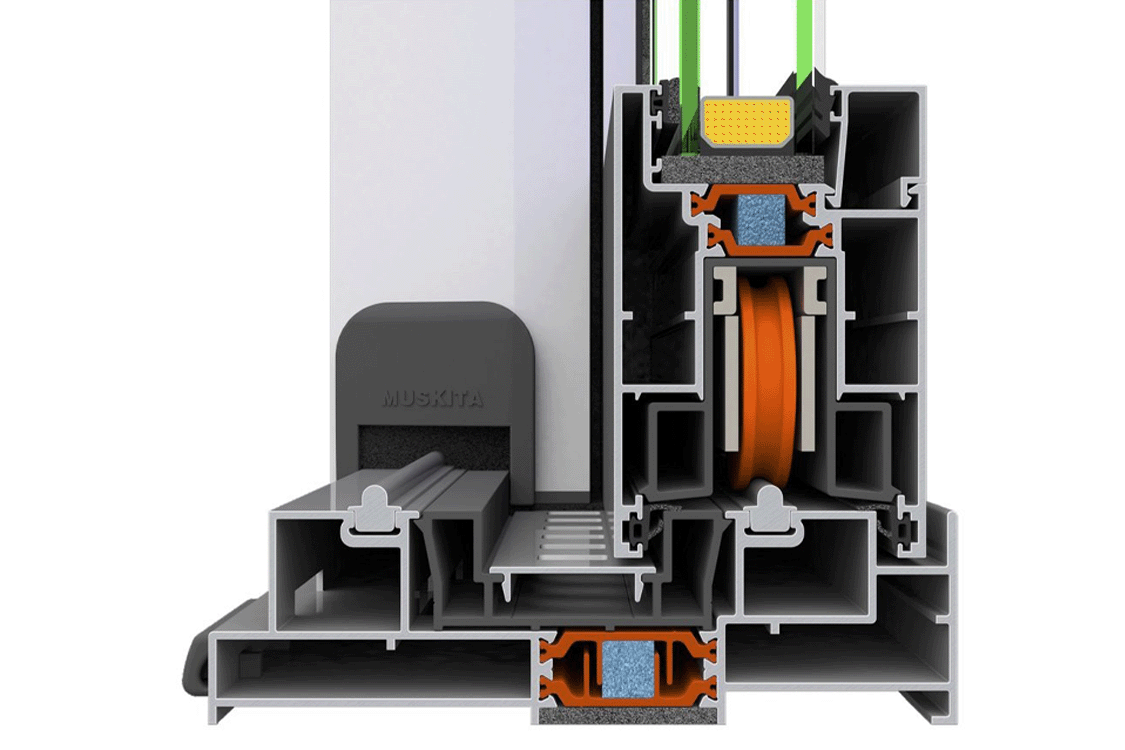

A thermal aluminium system prevents energy (heat or cold) from being transmitted from the outside to the inside of your home or vice versa. Good insulation rates and sound reduction are achieved by placing a polyamide (a poor conductor of heat) between the outer and the inner surface of the profile, which acts as a thermal break.

Thermal transmittance or the U-Value, is measured in W/(m²K) and is the amount of heat per unit time that can penetrate a square meter (1 m²) of construction material (e.g. frame) with a thickness d (m) over a period of one hour, when the temperature difference between these surfaces (inside vs. out) is equal to 1 degree (1°C).

U-values measure how efficient a material is as an insulator. Lower U-values indicate lower thermal loss and more insulation provided by the material.

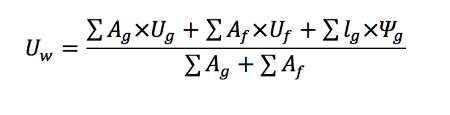

The following values are needed in order to calculate the overall U-value coefficient of a frame, otherwise known as Uw or U-window:

- Thermal transmittance of the glass (Ug - “glass”)

- Thermal transmittance of the frame (Uf – “frame”)

- The type of the glass spacer (“spacer”)

- Percentage of frame area relative to the total frame area

The Uw (U-window) is calculated by the following equation:

Where:

- Ug is the Thermal transmittance of the glass

- Uf is the Thermal transmittance of the frame

- Ψg is the linear heat transfer for different spacers

- Ig is the perimeter of the visible glazing frame

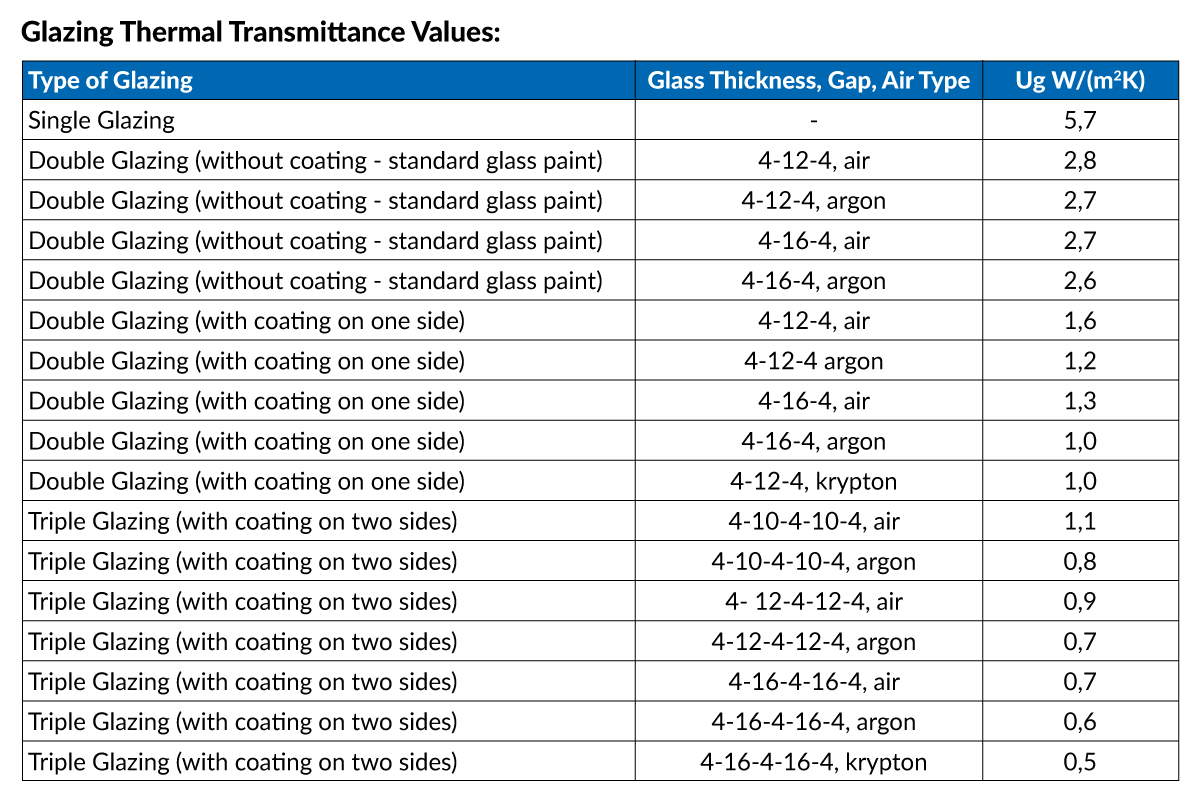

To achieve maximum thermal insulation, a low Uf coefficient for aluminum frames is required. However, the most important factor for a well-insulated window is the Ug coefficient of the glass.

The total thermal transmittance of a window (Uw), changes dramatically when we use glass with a lower Ug coefficient, since the glass surface is much larger than the surface of the aluminium frame. Because of this, it is very important to carefully choose the right aluminium system, as its energy efficiency is affected by several parameters. The most accurate way to compare two aluminium systems is using the Uf coefficient, or by using the exact same glazing type and dimensions in order to calculate the total thermal transmittance (Uw).

Several values for the thermal transmittance of the glass Ug coefficient can be found in Table 1 below:

In energy efficient thermal systems, the outer aluminum profile is separated from the inner profile by polyamides that thermally break the profiles, leading to excellent energy savings for both heating and cooling. Polyamides are visible on the side of the sash, so you can confirm that the frames you have in your home are thermally insulated.

Thermal or Non-Insulated Systems: What should I choose?

Using non-insulated aluminium systems, consumes up to 40% more energy for heating and cooling. By choosing thermally insulated aluminum systems you can avoid wasting energy and therefore save money.

In energy efficient thermal systems, the outer aluminum profile is separated from the inner profile by polyamides that thermally break the profiles, leading to excellent energy savings for both heating and cooling. Polyamides are visible on the side of the sash, so you can confirm that the frames you have in your home are thermally insulated.

Changing Your Aluminium Systems: What to consider

If you have decided to change your aluminium systems, it is advisable to replace the entire frame. Don’t just change the glass of existing non-insulated frames. Aluminium as metal is good conductor of heat, therefore, changing only the glazing will lead to condensation of water vapor on the inside of the glass created by the temperature difference from inside to outside. The solution to this is to use thermally insulated aluminium frames.

Energy Efficient Glazing: The Combination for the Perfect Result

In order to achieve maximum thermal insulation, it is vital to choose energy-efficient glass panes. Glazing takes up the largest surface area of the frame and must be chosen carefully. Our aluminum systems cover all possible frame configurations, including triple glazing, ensuring excellent energy efficiency, sound reduction and safety.

Installation Tips

When installing thermal aluminium systems, specialised sealing gaskets and plugs must be placed around the frame, between the flooring and masonry. This prevents the loss of heat or cold and preserves the thermally insulating properties of the system. In addition, all joints must be sealed with silicone.

Your aluminium fabricator can inform you about the thermal coefficient of the system you have chosen. At MUSKITA we can also help you evaluate your system's heat transfer coefficient with our state-of-the-art thermal cameras.