Aluminium is named

Sir Humphry Davy, an English chemist and physicist who employed electrolysis to extract new chemical elements such as potassium, sodium, magnesium and more, ascertained that electrolysis can also be used to extract a new metal from alum. He named this new metal aluminium, after alumen, which in Latin means bitter salt.

Bauxite discovery

Deposits of red rock were discovered in southern France by geologist Pierre Berthier. These rocks - named after 'Les Baux', the region they were found - were mined and then had the water from the ore extracted: leaving a white powder called 'alumina' behind. Bauxite would later be used as the primary raw material for aluminium production.

Element discovered

Following Sir Humphry Davy’s work, the Danish chemist Hans Christian Orsted was the first to successfully produce minute amounts of aluminium by reacting anhydrous aluminium chloride with potassium amalgam.

Precious aluminium

It was not until French chemist Henri Sainte-Claire Deville improved the methods of producing aluminium that it was able to be made available. Resembling silver, lightweight and expensive, aluminium was considered an elite metal. It was used to make jewellery and art. The first known items made of aluminium were medals with bas-reliefs of Napoleon III of France, as well as baby-rattle for his son Prince Louis Napoleon. Napoleon III even had it made into utensils that were reserved for only his most honored guests.

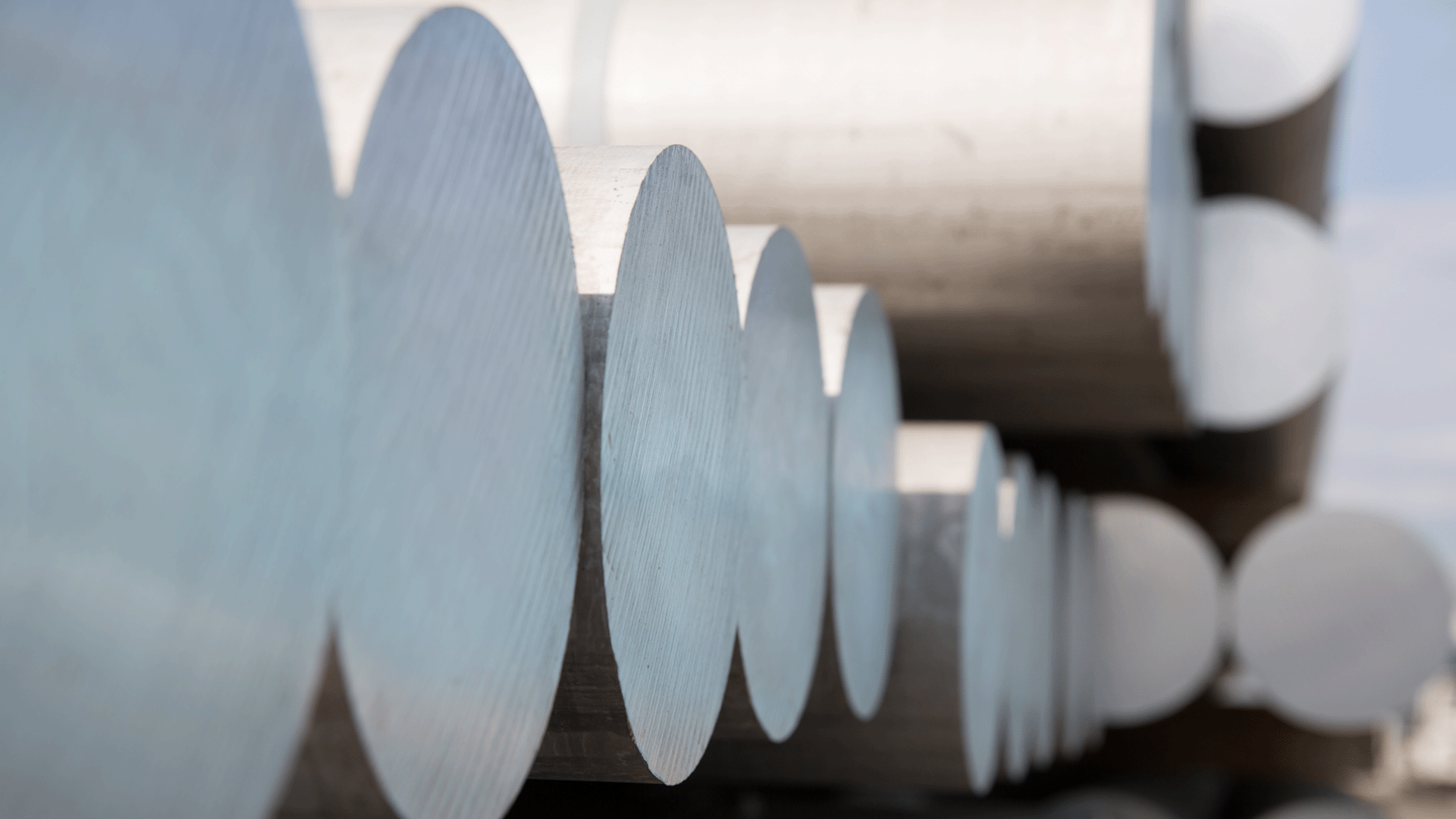

Smelting process still used today

Discovered simultaneously and independently by both French engineer Paul Heroult, and American student Charles Hall, the Hall-Heroult smelting is still being used today. It involves dissolving alumina, aluminium oxide, in molten cryolite, and electrolysing the molten salt bath.

Method is perfected

Karl Joseph Bayer, an Austrian chemist invented a cheap and feasible alumina production method by adding bauxite into an alkali solution and heating it. The aluminium dissolved into the alkali solution, yielding higher concentrations and productions of alumina. Merged with the Hall-Heroult process, the Bayer and Hall-Heroult process is still used today.

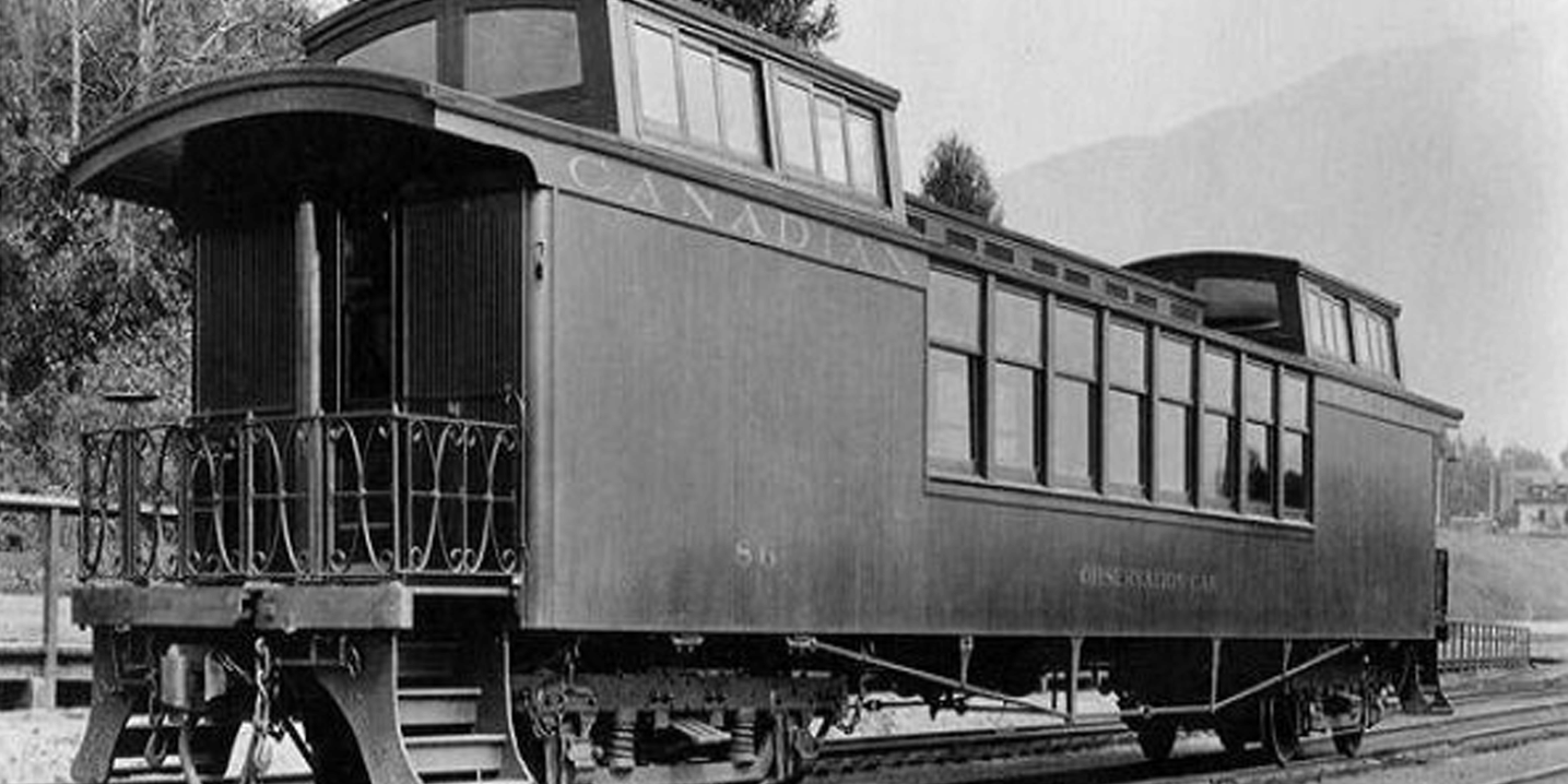

The first larger scale uses

With the manufacturing of aluminium now being industrialized, new ways of using the light metal began to appear. In 1891 Alfred Nobel commissioned the creation of the first passenger boat, Le Migron, with an aluminium hull in Switzerland. Three years later, J.P. Morgan commissioned the first lightweight passenger railroad cars with aluminium seats for the American Railway in New Haven, New York. At a 1899 exhibition in Berlin, Karl Benz presented the first sports car with an aluminium frame.

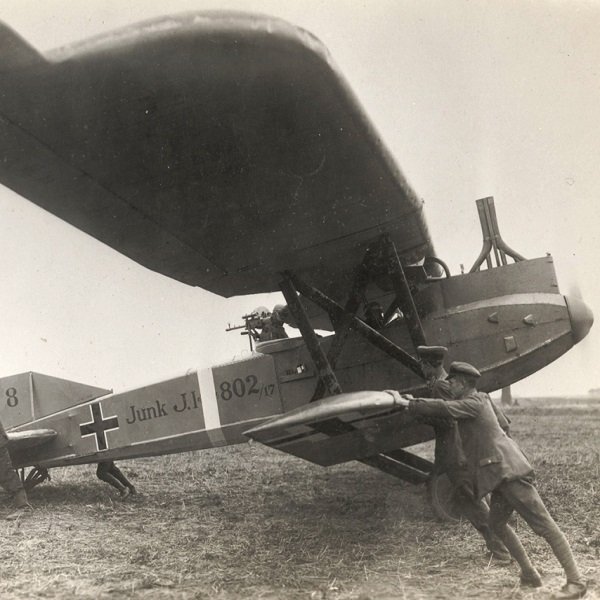

Duralumin is invented

The German scientist Alfred Wilm created duralumin by adding copper, magnesium, and manganese to aluminium. This made it much stronger, harder, and elastic, but kept it just as lightweight. From this moment on, it became the preferred metal for aviation with the first fully aluminium plane, the Junkers J 1 being made in 1915.

Chocolate in a foil wrapping

Tobler, a Swiss chocolate company, was the first to use aluminium foil for chocolate packaging. The famous triangle shaped Toblerone bar, among other products, was wrapped in aluminium foil which helps preserve the moisture of the chocolate.

The Empire State building

With aluminium being widely used throughout aviation, automotive, and shipbuilding, it was a matter of time until it moved to civil engineering. The Empire State Building in New York, became the first building to feature extensive use of aluminium in the construction of both the basic structure and the interior. One of the building’s architectural features, a fresco painting on the ceiling and walls of the lobby, was carried out in aluminium and 23- carat gold.

Aluminium Façade

In 1952 the construction of the 30 floor United Nations Headquarters in New York was complete. This was the first building in the world designed to feature a translucent façade made of glass and aluminium sections.

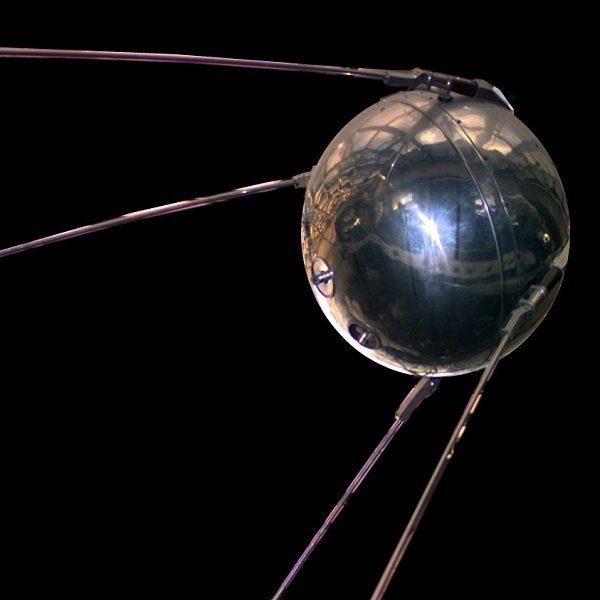

The Move to space

The USSR launched the first artificial satellite into orbit that was made of two semi-spherical hulls joined together. The hulls were made entirely of aluminium, setting the way for aluminium to become an important component in aerospace engineering.

The first aluminium cans

Kaiser Aluminum and Coors were the first to use aluminium in the making of cans. The first drink to be sold in can form was beer, and by 1967 it had become an industry standard with Coca-Cola and Pepsi also transitioning to aluminium cans. The can manufacturing company Coors began organizing the first can collections for recycling nearly as soon as they were invented.

Boeing 747

The world’s first wide body passenger aircraft completed its first commercial flight from New York to London on behalf of Pan American World Airways. Boeing 747 can transport as many as 660 passengers and a single Boeing 747 requires over 66 tons of aluminium.

London Metal Exchange

With ever growing global demand and production for aluminium it became an exchange commodity and entered the oldest exchange in the world, London Metal Exchange. Since then, the price of primary aluminium has become globally uniformed, and fluctuates based on exchange trades on the LME.

International Space Station

The first component of the International Space Station, the largest artificial satellite of our planet, was launched into the Earth’s orbit. A large portion of the space station was made of aluminium alloys.

The Future

With endless uses for aluminium, it has become an intrinsic part of our everyday lives. It has revolutionized every industry it has entered, and so many future possibilities are still yet to be discovered. From space stations, to everyday objects like our smartphones, aluminium has helped form the world around us, and let our architectural, engineering, and ecological minds run wild. The future of aluminium is brighter than ever, with it being both so durable, and easily recyclable. We have yet to see its full potential.