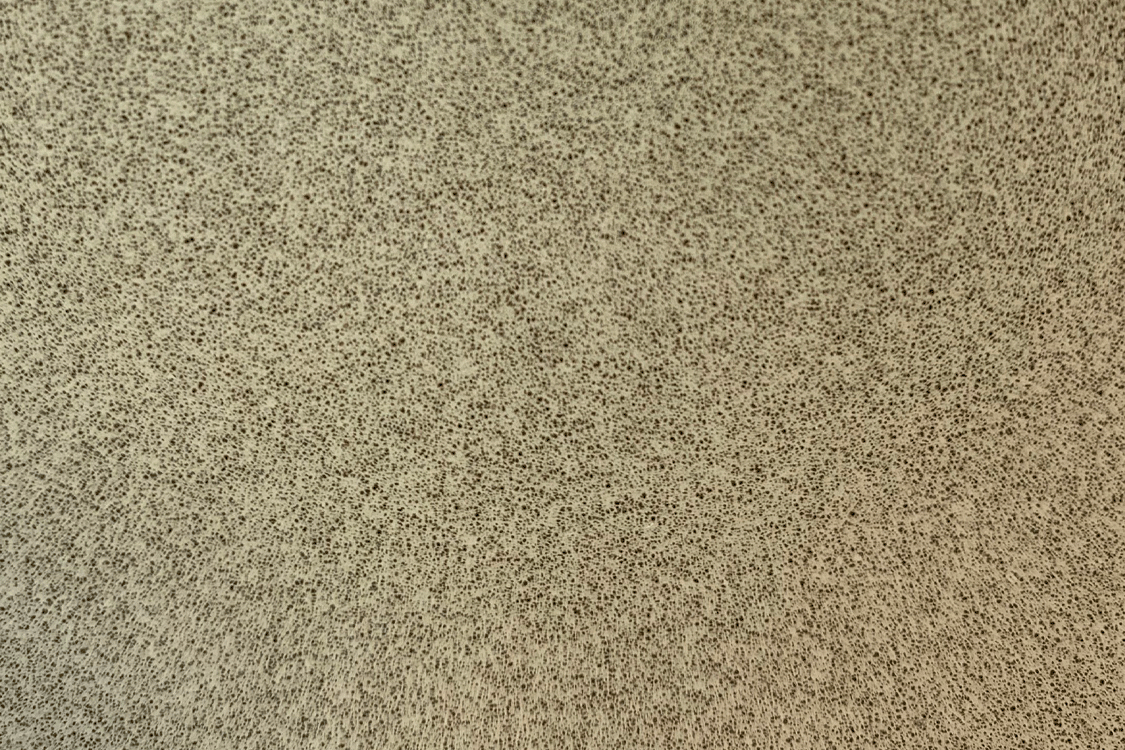

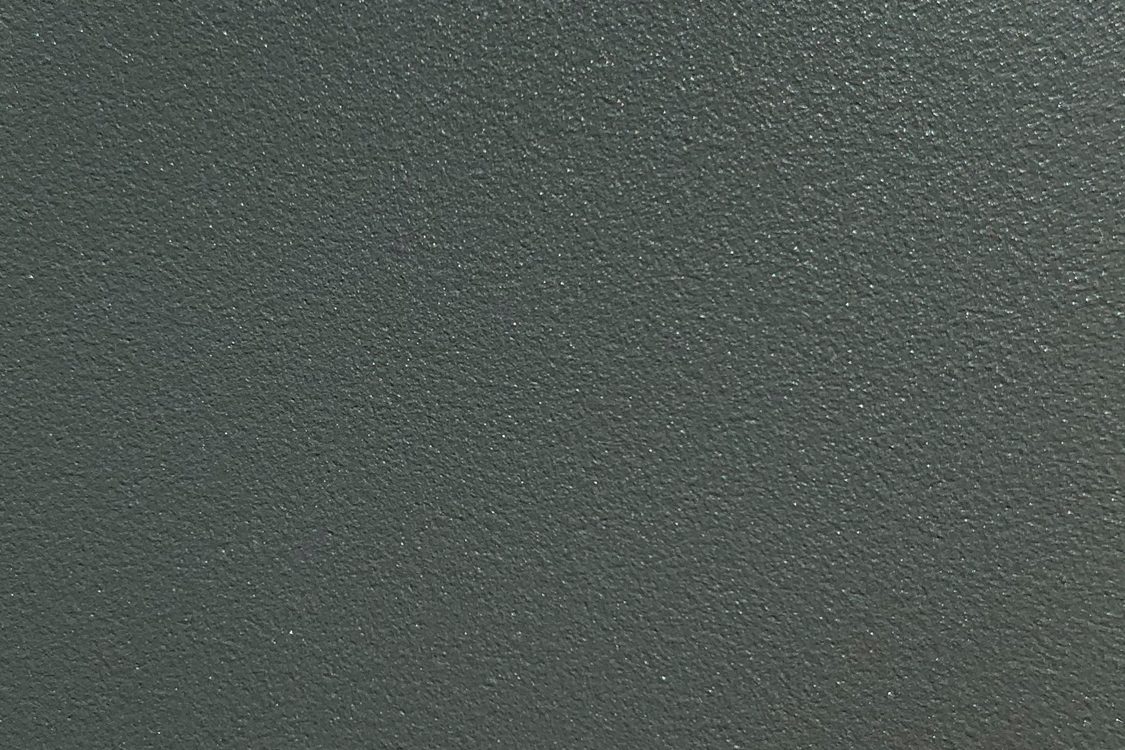

MUSKITA's Superdurable Powder Coating collections are composed of a range of specialty MU finishes created exclusively for MUSKITA together with standard RAL colours. The collections consist of comprehensive palettes of high quality soothing sophisticated shades, classic hues and earthy tones with smooth or sanded matt textures, offering a wide range of options for every style and need.

Our powder coating finishes are made with Superdurable Class 2 polymer technology. This ensures they meet and exceed the strictest industry requirements and standards of QUALICOAT Class 2 Superdurable powders, achieving durability three times that of Class 1 finishes. Their superior quality together with their excellent durability and resistance against weathering agents makes powder coating finishes ideal for projects with high performance requirements.

Please note the colours & finishes shown here vary from the final product. For an accurate representation, visit our showrooms to see them in person.

Recommended cleaning includes rinsing with water followed by a soft sponge with water and soap (such as dishwashing liquid), then rinsing with water and drying with a soft cloth. It is recommended that cleansing products have a pH between 5.5 – 8 (should neither be acidic or alkaline). Cleansing products which include chlorine or soda must be avoided. Construction materials such as cement, lime, plaster or adhesive tape must be removed immediately after installation. Moreover, silicone residue should be removed with cotton wool and blue spirit. It should be noted that in industrial and coastal areas cleaning of should be more frequent.

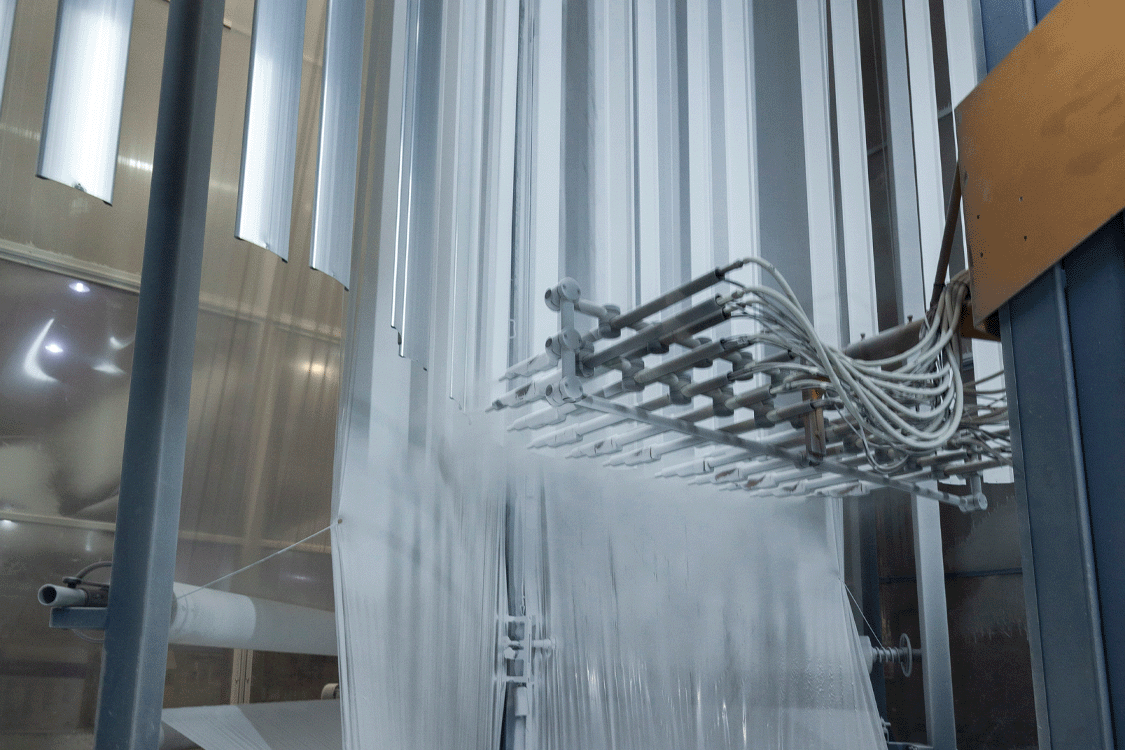

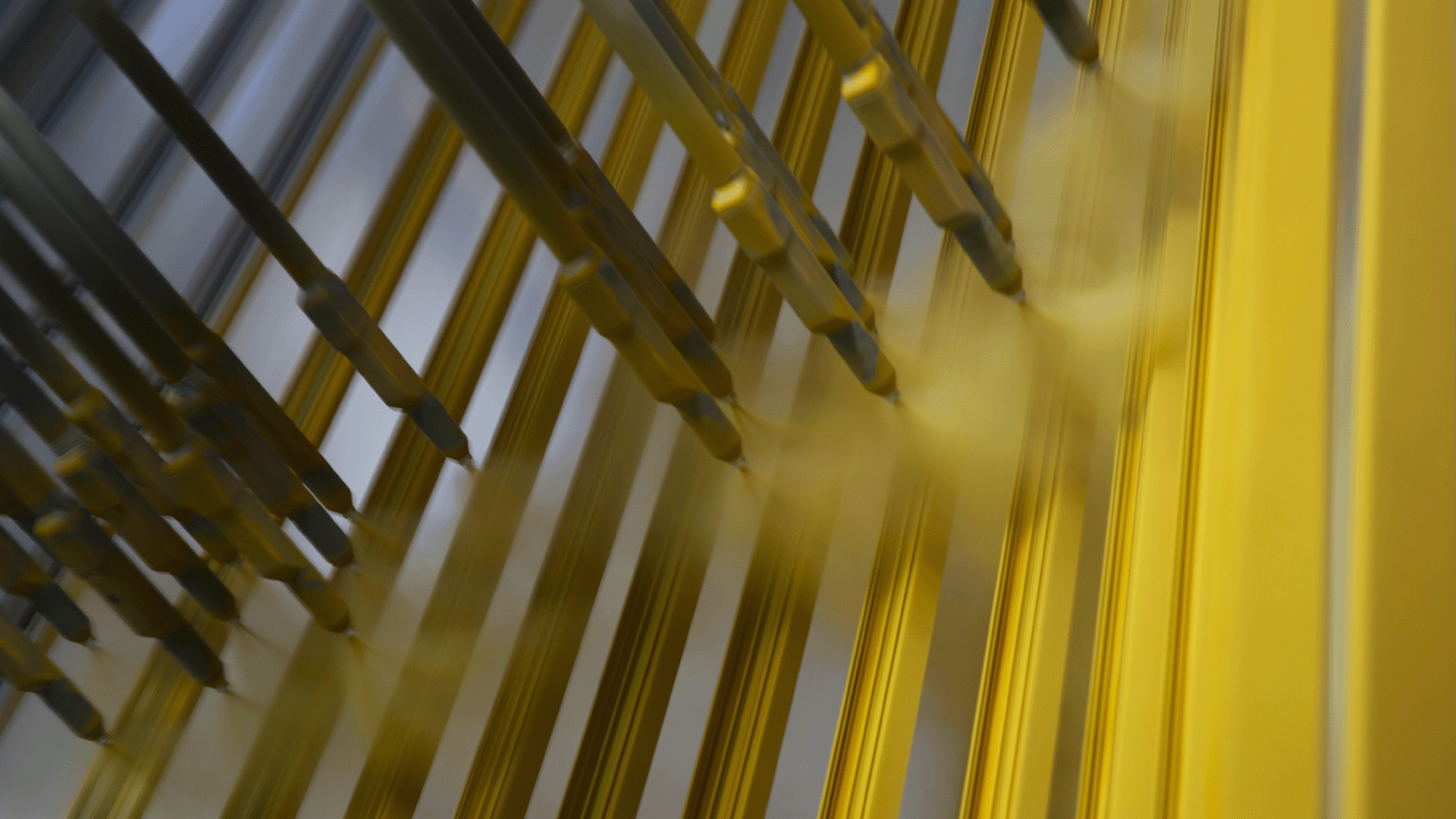

MUSKITA is one of the largest independent powder coaters in Europe, operating state-of-the-art robotic powder coating plants. Our vertically integrated production facilities combined with our in-house powder coating process give us complete control over product quality, from raw materials to finished products for outstanding results.

Our products are certified by the quality certification QUALICOAT since 1985.