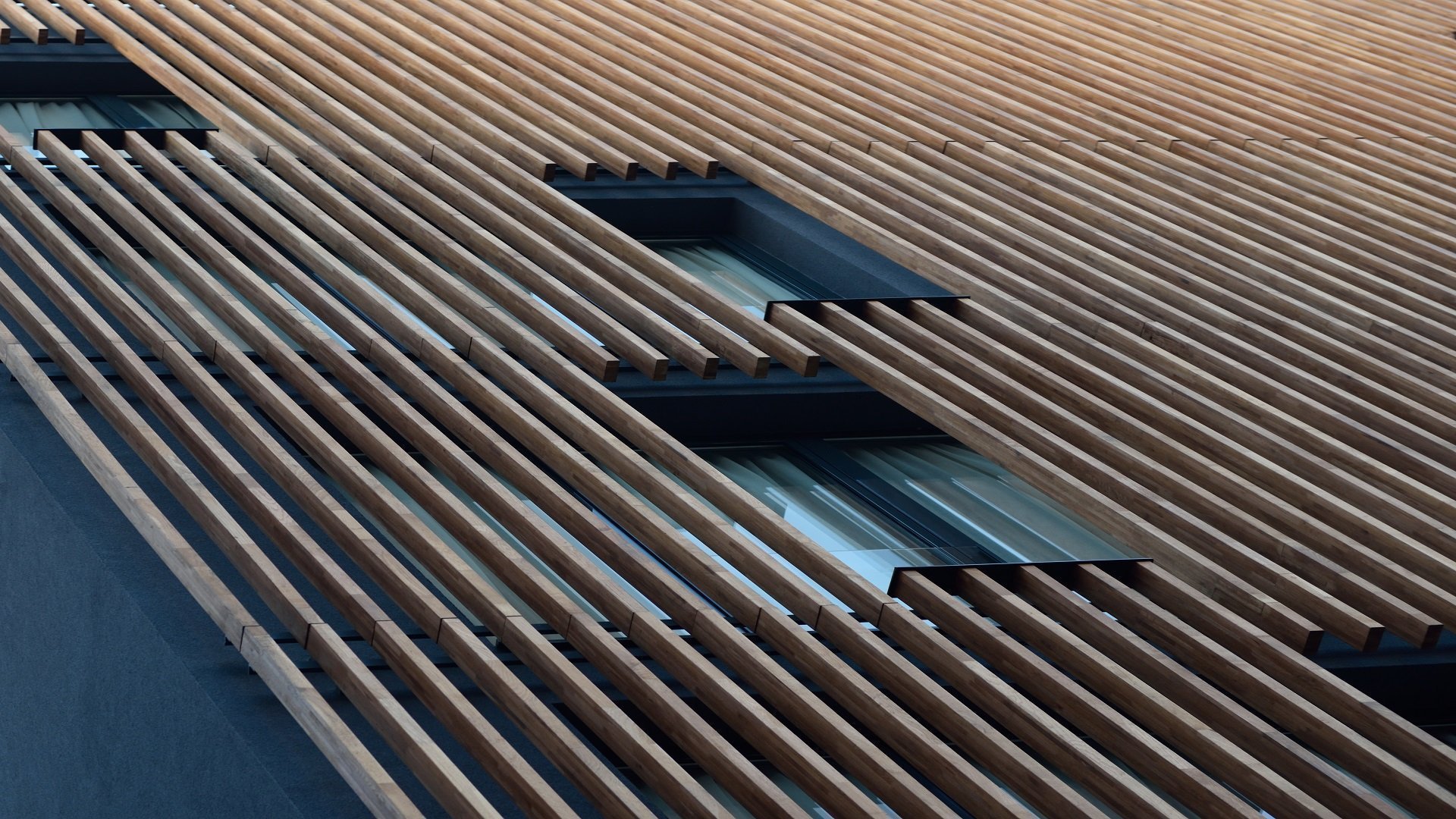

MUSKITA maintains and operates one of the most advanced factories worldwide utilizing state of the art robotic technology. Our vertically integrated production facilities combined with our in house Decoral process give us complete control over product quality, from raw materials to finished products for outstanding results.

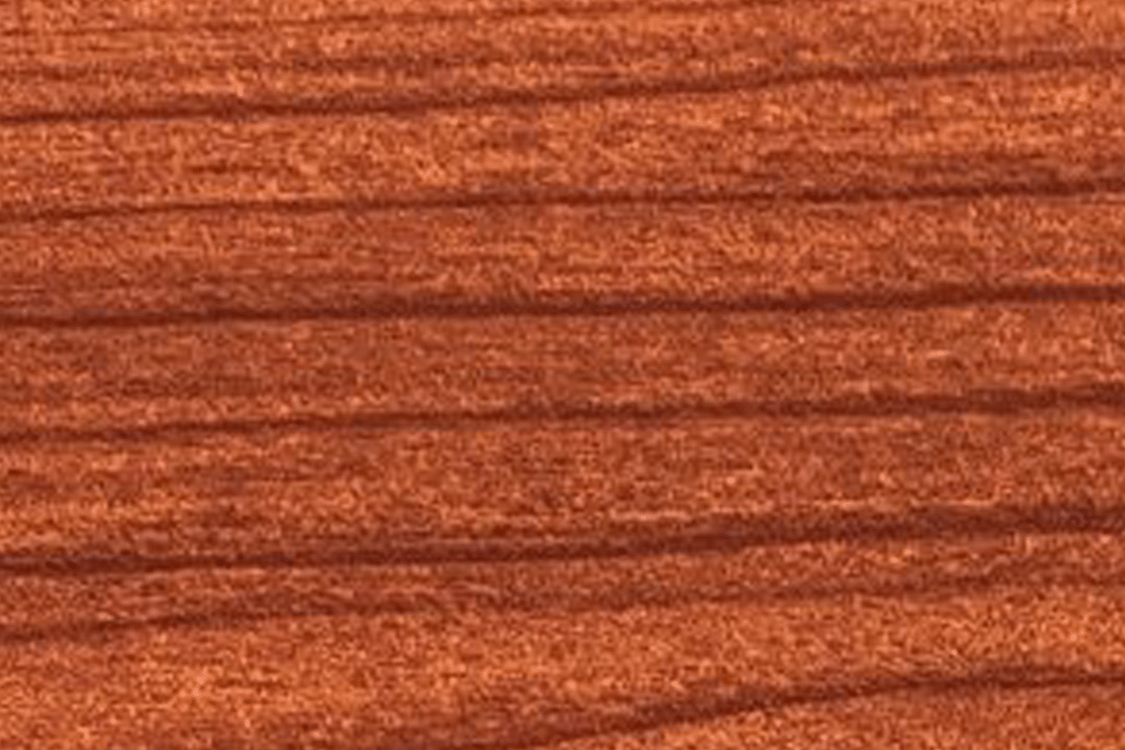

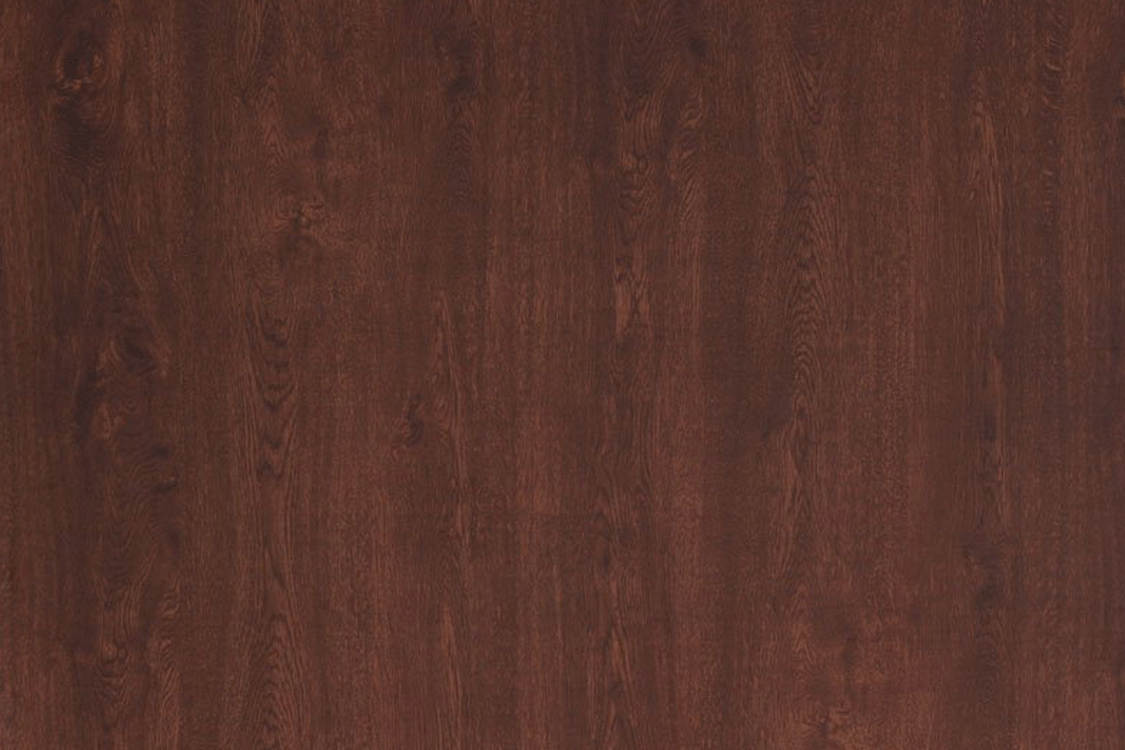

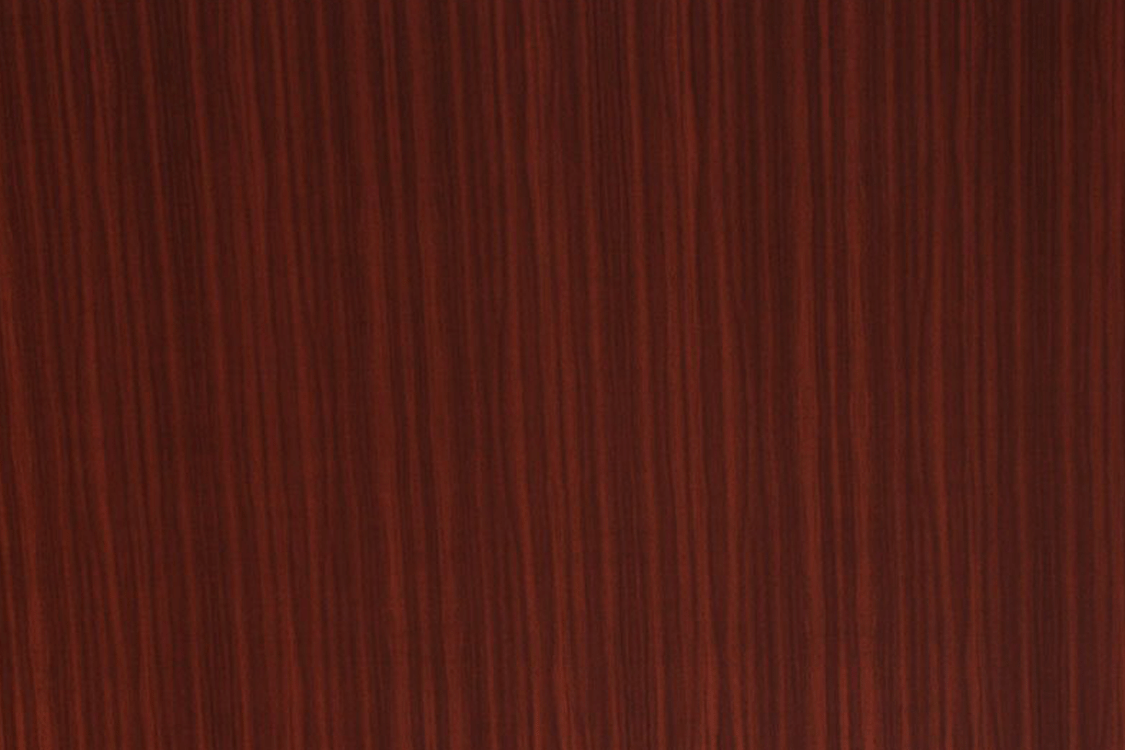

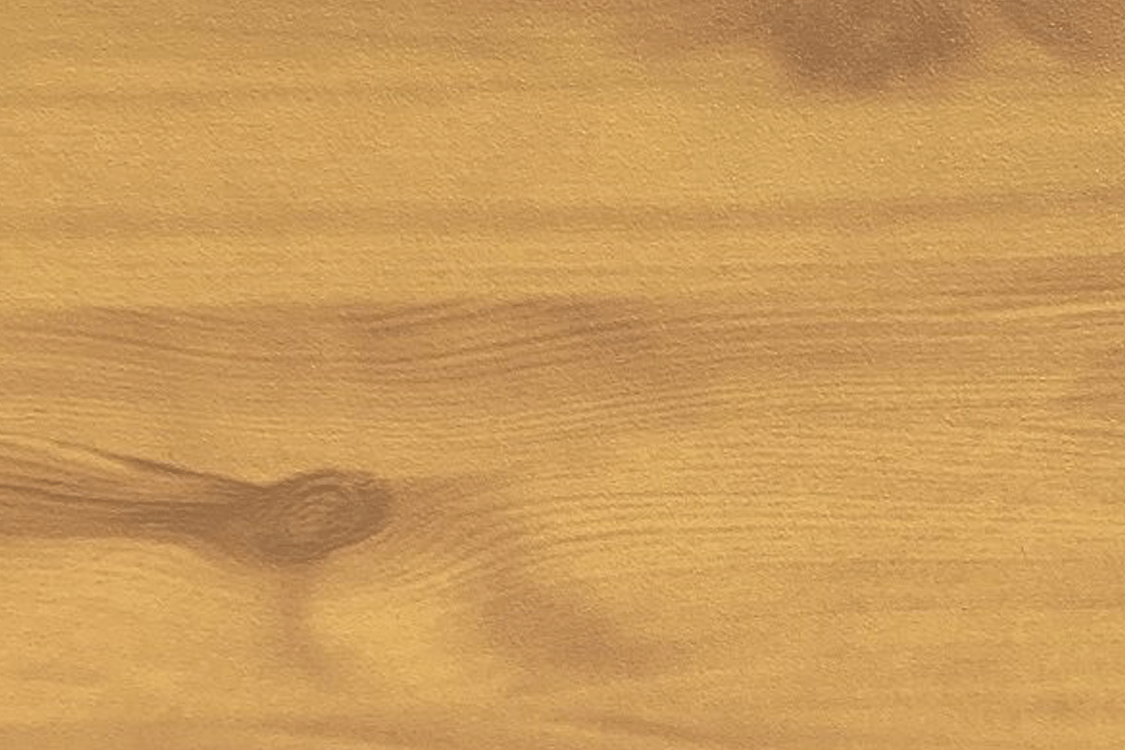

Please note the colours & finishes shown here vary from the final product. For an accurate representation, visit our showrooms to see them in person.

Our wood finishes are made with Superdurable Class 2 powder coating technology. This ensures they meet and exceed the strictest industry requirements and standards of QUALICOAT and QUALIDECO Class 2 Superdurable powders, achieving durability three times that of Class 1 finishes. Their superior quality together with their excellent durability and resistance against weathering agents makes wood finishes ideal for projects with high performance requirements.

Decoral® is a process for decorating the aluminium surface with effects and patterns creating a unique aesthetic. The Decoral® process is based on sublimation, a physical-chemical process which is the direct transition of a specific substance from a solid to a gas state without passing though a liquid phase.

Aluminium is first treated in a Decoral® polyurethane powder coating system consisting of three stages: pre-treatment, powder spraying and curing. After cooling down from coating, the aluminium is vacuum wrapped with a specialized Decoral® Heat-Transfer film causing the film to adhere perfectly to the aluminium surface. The aluminium is then cured in a special Decoral® Oven and inks contained in the film are transferred by sublimation into the coating layer of the aluminium. The special inks achieve penetration to the entire depth of the coating layer for maximum durability.

Although wood finishes are highly durable and require minimum maintenance, it is recommended the aluminium be cleaned periodically.

To remove dust deposits and other pollutants, recommended cleaning includes rinsing with water, cleaning with a soft sponge with water and soap (e.g. dishwashing liquid), rinsing with water and drying with a soft cloth. Cleaning products should have a pH between 5,5 - 8. Cleaning products that include chlorine or soda should be avoided. Construction materials (e.g, cement, lime, plaster, adhesive tape) must be removed immediately after installation. Silicone residues should be removed with cotton wool and blue spirit. In industrial and coastal areas cleaning should be more frequent.